Wrought iron is often used in the business sector due to the power that the material has. Cast iron is far more challenging to work with than its cousin, wrought iron, which is more robust.

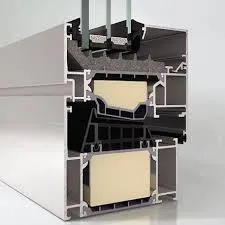

Common surface treatment processes for aluminum doors and windows are electrophoretic coating, fluorocarbon spraying, wood grain transfer coating, anodizing, and electrostatic powder coating. In most cases, after good surface treatment, aluminum profiles have good atmospheric corrosion resistance. It is moisture-proof, sunscreen, flame proof, aging proof, high-temperature deformation proof, low-temperature embrittlement proof, durable and stable, and suitable for various climates.

Sturdy

- Manufactured from high-quality materials such as stainless steel, brass, or even durable plastics, these handles are built to withstand the test of time. Their robust construction means they can support substantial weight without bending or breaking, making them ideal for both residential and commercial settings. The 400mm pull handle is not only reliable but also adaptable, suitable for a range of environments requiring robust functionality.

- Wrought iron and ornamental iron are two very different classifications of a very similar style of fence. Knowing the differences between the two types of fences and understanding the one right for you is the first step towards saving you both time and money on your fence project.

Unmatched Durability

- 9

1. Aesthetic Appeal The slim design of these aluminium profiles contributes to a clean and modern aesthetic. They can seamlessly integrate into various decor styles while providing a contemporary edge. This makes them particularly appealing for residential, commercial, and retail environments, where design plays a crucial role in attracting customers.

Design Versatility

6262 Aluminum Grade

6262 aluminum alloy contains silicon, magnesium, copper and chromium, which has good processability, corrosion resistance and strength. It can be used to make doors and windows, but it is not as common as 6063 aluminum alloy. Generally, this grade of material is selected for door and window projects with special requirements.

Another great application for aluminum profiles is those which can be found across many window frames. Though it may seem unconventional aluminum window frames have been utilized for both functional and decorative purposes.

Modern Applications

Inspect the seals and weatherstripping around your aluminum windows: Regularly inspect the seals and weatherstripping around your aluminum windows for any signs of wear, damage, or gaps. Replace damaged or worn-out seals to maintain proper insulation and energy efficiency. Clean the seals regularly to prevent dirt or debris buildup that can affect their effectiveness.

Of course, having decided to build with an aluminium frame profile you will have to decide what shape you want. As previously mentioned, this is the strongest material but it is also one that are not as widely available as some of the other materials. Therefore, you may find that it will be more cost effective for you to build with some form of shed roof. However, before you do this you should think about whether you actually want this feature or not.

There are differences in their chemical composition, but the primary difference between cast iron and wrought iron is in how they’re produced: cast iron is iron that’s been melted, poured into a mold (i.e. a “cast”), and allowed to solidify into its current shape. Wrought iron, on the other hand, is iron that’s been heated and hammered with tools (i.e. “wrought,” the archaic past tense of “work”) to form it into a precise shape.

wrought iron manufacturers. This finish can be painted, powder-coated, or left bare, depending on the desired aesthetic.

cast iron metal gates. Their solid construction and weight make them difficult to force open, providing peace of mind for homeowners. Furthermore, with proper maintenance, they can last for generations, acquiring a patina over time that only enhances their character.

cast iron metal gates. Their solid construction and weight make them difficult to force open, providing peace of mind for homeowners. Furthermore, with proper maintenance, they can last for generations, acquiring a patina over time that only enhances their character.Thermal Efficiency

price for wrought iron fence. Professional installation ensures the fence is secure, level, and meets local building codes. The complexity of the installation process, such as digging post holes, setting concrete, and attaching the fence panels, all factor into the total cost.

price for wrought iron fence. Professional installation ensures the fence is secure, level, and meets local building codes. The complexity of the installation process, such as digging post holes, setting concrete, and attaching the fence panels, all factor into the total cost.The Multifaceted Benefits of a Stainless Steel Box with Lock

What is Ornamental Iron Fence?

The Elegance and Strength of Main Gate Iron Gate Designs

ornamental iron post. Their robust construction acts as a physical barrier, deterring potential intruders while also creating a psychological sense of safety. They also define spaces, marking entrances, boundaries, and pathways with a distinct air of formality and grandeur.

ornamental iron post. Their robust construction acts as a physical barrier, deterring potential intruders while also creating a psychological sense of safety. They also define spaces, marking entrances, boundaries, and pathways with a distinct air of formality and grandeur.Quality Tests of Aluminium Profiles For Window/Door

It can be used in a wide range of settings, from residential homes to commercial businesses, and from personal use to institutional settings such as banks and government agencies It can be used in a wide range of settings, from residential homes to commercial businesses, and from personal use to institutional settings such as banks and government agencies

It can be used in a wide range of settings, from residential homes to commercial businesses, and from personal use to institutional settings such as banks and government agencies It can be used in a wide range of settings, from residential homes to commercial businesses, and from personal use to institutional settings such as banks and government agencies metal box with padlock. Its compact size and rugged construction make it ideal for storing items that need to be kept secure but also easily accessible.

metal box with padlock. Its compact size and rugged construction make it ideal for storing items that need to be kept secure but also easily accessible.